Never miss an update from Universidad de Alicante

Create your free account to connect with Universidad de Alicante and thousands of other innovative organizations and professionals worldwide

The University of Alicante has developed a method to transform the dynamic instruments for the determination of vapor-liquid equilibrium data into useful equipment for the determination of isobaric vapor-liquid-liquid equilibrium data by the application of ultrasound. Commercial equipment for homogeneous systems can be used for heterogeneous systems with this technique. Partners are sought to acquire the know-how and the patent rights.

TECHNICAL DESCRIPTION

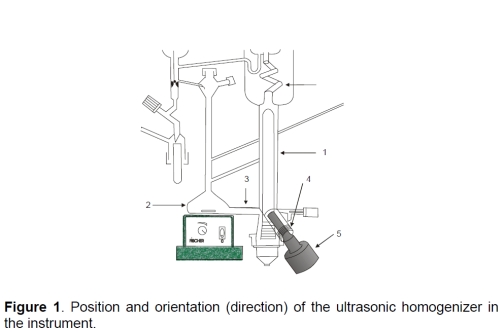

Using a standard equipment for the determination of the VLE in homogeneous systems, the developed method consist of applying an ultrasound bean to the liquid-liquid-vapor mix by means of an ultrasonic probe (5) coupled in a welded and communicated tube (4) to the reboiler (1). The tube (4) and probe (5) are situated in the reboiler (1) at the pipe (3) level and in contact with the mixer flask (2). An hermetic closing between the probe (5) and the tube (4) is established to avoid leaks of liquid and / or vapor as well as any acoustic energy loss to the liquid-vapor mix. Figure 1 shows this arrangement.

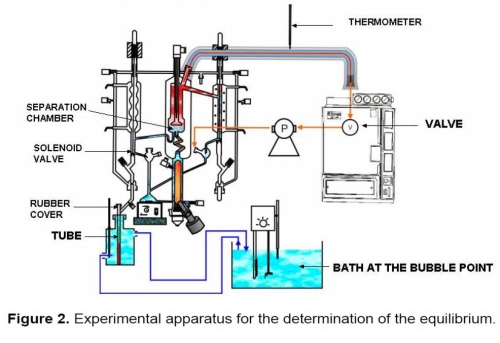

The functioning of the VLLE determination equipment is similar to the equipment without probe for homogeneous liquids but including one more parameter to be controlled. That is the ultrasound power. The ultrasound power must produce a constant emulsion in the reboiler in order to avoid the two liquid phase separation.

Samples of recirculated liquid for the two phases analysis are taken almost in the same way that when the liquid is homogeneous. In this case, samples are taken from thermostated tubes at the same temperature than in the mix vapour bubble point (measure by the apparatus ). Like this, there is time enough to the separation of two liquid phases at this temperature, sampling and analysis.

Taking samples from the vapour phase can be done after condensation if the condensed vapour produces a homogeneous liquid. In case of being heterogeneous, direct analysis of the vapour without previous condensation is the optimum procedure for the composition determination.

Figure 2 shows the experimental equipment as well as the assembly for the taking of samples in the liquid and vapour phases.

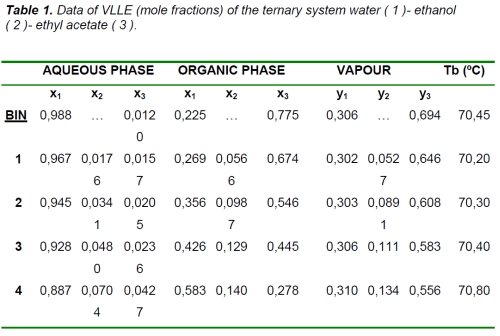

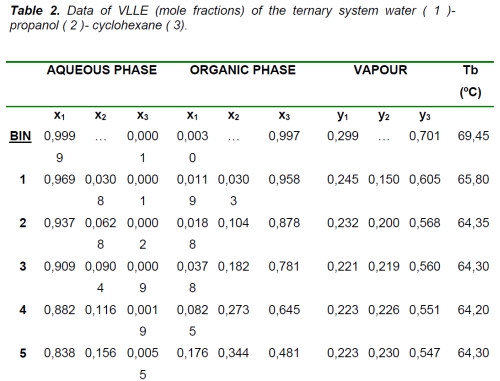

Following tables show the VLLE data from the two ternary systems determined experimentally by using this new method. Every table shows compositions (mole fractions) of the liquid and vapour phases as well as the bubble temperatures. The power supplied by the ultrasound generator to determine the VLLE data of both systems was lower than 100 watts.

The VLLE data from both systems intended to be obtained in the original equipment Labodest WITHOUT MODIFYING it. Reliable data could not be obtained. Also for poor propanol ternary mixes of the system water-propanol-cyclohexane was impossible to determine the equilibrium due to the great system unstability where important temperature oscillations were producing (over 10ºC in some cases). Also was impossible to determine the equilibrium in the range of poor ethanol concentrations for the system water-ethanol- ethyl acetate due to the scarcity (in some null cases) of the recircultated organic phase trough the Cottrell pump.

TECHNOLOGY ADVANTAGES AND INNOVATIVE ASPECTS

- Ultrasound application on the VLLE determination is a new technique.

- The number of ternary systems with experimental VLLE data is very limited since there is no commercial equipment to sample separately the three phases in equilibrium. This method allows to obtain data from this systems.

- Current equipment for homogeneous systems can be used for heterogeneous systems with this method.

CURRENT STATE OF DEVELOPMENT

The method has been tested at laboratory scale after many experiments. Position and direction of the ultrasound probe has been optimised. An efficient method to produce an hermetic closing between the probe and the tube has been also established.

This method has been implemented in one of the most utilized equipment nowadays for the isobaric VLE data determination: the Labodest from Fischer Labor und Verfahrenstechnik, Germany). Applying some ultrasound beam (homogeneizador> ultrasonic homogeneizator Labsonic L –from Braun –) the original equipment is transformed to one equipment capable of the isobaric VLLE data determination in heterogeneous systems.

COLLABORATION SOUGHT

The Department of Engineering Chemistry of the University of Alicante is looking for partners interested in:

- Acquiring the know-how and the patent rights to manufacture and commercialise equipment for the VLE experimental determination according to this new method.

- Establishing research and development projects in the field of phase equilibrium.

Ahead of the current Coronavirus outbreak, Innoget is fully committed to contributing to mobilizing scientific and expert communities to find a real solution to the Covid-19 pandemic. Therefore, we're supporting worldwide calls and programs that could help in any aspects of the coronavirus crisis.

Is your organization promoting or looking for innovation or research initiatives to mitigate the Covid-19 outbreak? Email us at covid19@innoget.com to list them.

Channeled through Innoget's online open innovation network, initiatives in the health, virology, medicine, or novel technologies applied to human health, among others, are listed and disseminated to Innoget members -ranging from hospitals, research institutes, scientists, businesses, and public administrations- and innovation partners worldwide.

Create your free account to connect with Universidad de Alicante and thousands of other innovative organizations and professionals worldwide

Send a request for information

to Universidad de Alicante

Technology Offers on Innoget are directly posted

and managed by its members as well as evaluation of requests for information. Innoget is the trusted open innovation and science network aimed at directly connect industry needs with professionals online.

Need help requesting additional information or have questions regarding this Technology Offer?

Contact Innoget support