Photocatalytic material for disinfection and self-cleaning

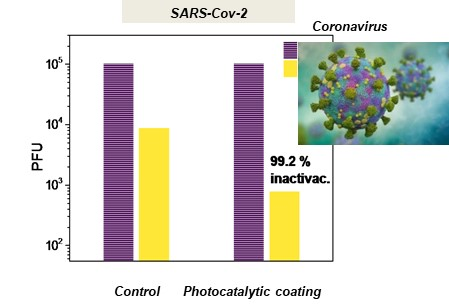

Inactivation results for the photocatalytic coating. Plaque-forming units (PFU) of SARS-CoV-2 under dark conditions: L (violet) or illumination conditions: L (yellow). The World Health Organization insists that preventive actions must be taken against pathogenic microorganisms and European legislation requires the development of more efficient products, more ecological and without toxicity for preventing microorganism proliferation. In this context, this coating has a high potential.

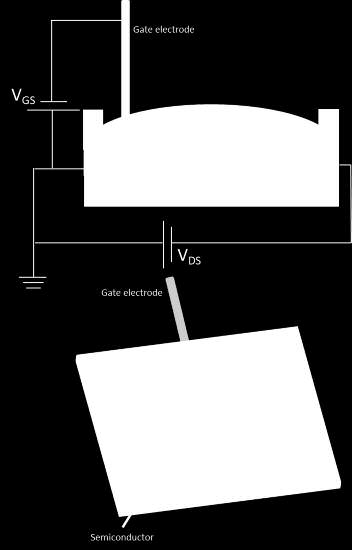

This material is made up of nanoparticles of two semiconductors. The heterojunction or composite is activated under lighting conditions and produces high oxidative stress on the lipid envelope and membrane proteins of the microorganism, cancelling its ability to infect cells or causing their death (in the case of bacteria). Furthermore, surfaces remain free from bacterial colonization and biofilm formation. This gives them very efficient biocidal properties, preventing the proliferation of microorganisms on surfaces and their subsequent transmission.

Several viruses and bacteria relevant to human health were tested with the material reaching inactivation higher than 99% for viruses, under lighting, conditions and inactivation of 100% for gram negative bacteria (E. coli) and a decrease of mora than five logarithmic colony forming units for gram positive Bacteria (S. aureus) under lighting conditions too. Under dark conditions inactivation results are lower, especially for viruses.

Main innovations and advantages

· The material can be used as a coating for different surfaces: metals, ceramics, textiles, work surfaces, instruments, swimming pools, etc…

· The composite is very stable, easy to synthetize and low cost.

· The material shows low toxicity, being biocompatible in contact with the skin.

· The coating is stable and resistant to abrasion and washing without losing its activity or releasing material.