CSIC and the University of Zaragoza have developed a novel dual membrane that consists in a porous matrix wherein after the etching of molten salt (usually carbonates but not limited on them) allows the transport of CO2 through the membrane as carbonate ions. The high permeability is attributed to the excellent pore alignment, micrometric diameter, high specific internal surface and the long reaction line among the feed gas, the ceramic and the molten salt.

Industrial partners are being sought to collaborate through a patent licence agreement and/or R&D.

A highly permeable and selective membrane.

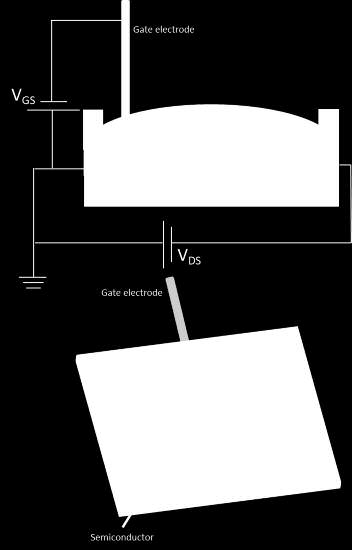

The climate change and the global warming induced by greenhouse effect gases such as CO2, urge to search forms of separating and storage the CO2 emitted in industrial processes. Among devices that may serve to such goal at high temperature, the CO2 selective dual membranes present two main properties, permeability and selectivity to said gas. Membrane permeability depends both on intensive factors of the constituent materials, such as the support and molten salt conductivities, as on geometrical factors (membrane thickness) and support microstructural properties, mainly of its porosity and tortuosity. In this patent we propose some materials and two procedures that produce supports with highly aligned micrometric pores and with a high specific surface area: unidirectional solidification, which provides supports of a few mm in diameter, and surface melting, which achieves surfaces above cm2.

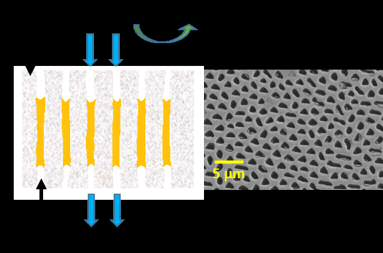

L: Schematics of the membrane formed by a porous ceramic matrix and molten-carbonate.

R: Electron micrograph of porous matrix obtained from the eutectic of the ZrO2-MgO system.

Main innovations and advantages

- High permeability compared to current technologies: an order of magnitude greater than in membranes based on similar compounds and of the same order as the best performance reported with other oxides.

- Through the solidification technique used, optimal characteristics of the pore structure (percentage, dimensions and tortuosity) are achieved.

- The technology allows excellent alignment of pores with controllable diameter in the range of 1 to 20 µm.

- The surface melting technique is applicable in flat or cylindrical geometries, as well as in self-supporting or supported configuration.

- The supports developed can be infiltrated with other molten salts, depending on the gas to be separated.