Summary of the technology

Reinforced packaging paper

CSIC, through INIA-CSIC and its Forestry Research Center (CIFOR), has developed a method to increase significantly the compressive strength and stiffness of packaging paper, comprising the application of a bio-product obtained from lignocellulosic waste, without having to submit it to additional handling stages. The desired weight and strength is achieved without the need to add cellulosic fibers or strength additives nor subjecting the paper to additional stages of manipulation.

We are looking for companies in the paper and cardboard industry and the chemical industry dedicated to the manufacture of additives interested in the development of this technology.

An offer for Patent Licensing

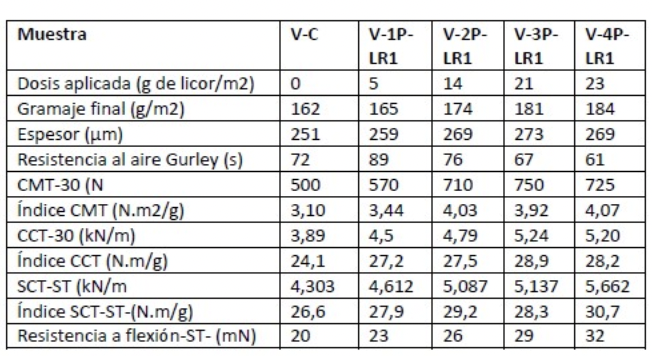

Paper with high stiffness and compressive strength

Comparative results with a control (V-C) and papers reinforced with different doses of residual liquor (1% of suspended solids) Corrugated cardboard for containers and packaging is capable of withstanding high mechanical stresses and has a very favorable utility/price ratio and sustainability. Currently, to reduce the amount of waste generated, there is a tendency to manufacture lighter boxes, reducing the grammage but at the cost of reducing the mechanical resistance of the paper. This makes necessary to develop methods that provide resistance to the paper with a lower amount of fiber while keeping its performance.

For this purpose, we propose treating the paper with a residual liquor obtained by the pretreatment of lignocellulosic residues with alcohol-water and subsequent drying.

The liquor has a solid fraction (1-70%) formed by lignin-carbohydrate complexes, as well as a liquid fraction (99-30%) that contains hemicelluloses, hydrolyzed lignin and degradation compounds, mainly acetic acid and furfural. The result is a reinforced paper that exhibits a surprising increase in compressive strength and stiffness.

Main innovations and advantages

- The applied product is bio-sustainable and does not require chemical processing after it is obtained · Absence of sulfur makes the reinforced paper suitable for all kinds of uses including food.

- The application system is versatile and can be applied at various points in the paper machine and also in the manufacture of corrugated cardboard.

- The use of lignocellulosic residual liquor allows to reduce the consumption of vegetable fiber in the reinforcement of the paper because the liquor itself can substitute a part of this fiber, obtaining the desired grammage.

- The compressive strength of the paper increases proportionally to the amount of residual liquor added, which makes it possible to design the type of paper according to the dose of product applied.

Intellectual property status

- Granted Patent

- Patent application number :-

Related Keywords