CSIC has developed a novel catalyst, with a simple preparation method, that achieves the removal of 98% of N2O emissions at temperatures below 350ºC, when applied in the so-called "tail gas" of nitric acid production plants (tertiary treatment) and under real manufacturing conditions (presence of water, oxygen and at high spatial speed).

Industrial partners, from the chemical sector and interested in the production or the use of this catalyst, are being sought to collaborate through a patent licence agreement.

N2O abatement at low temperatures

The invention consists on a new solid catalyst for the tertiary treatment of nitrous oxide emissions. The material shows a significant improvement in the catalytic activity, allowing the use of lower volume of catalyst at lower temperatures, for the N2O removal.

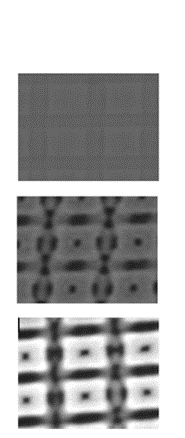

The catalyst was tested under real operating conditions of a nitric acid production plant: 1400 ppm N2O, 3% O2, 0.5% H2O and a catalyst flow/volume ratio of 50,300 h-1, resulting in N2O conversion value of 98% at 340ºC.

100 N2O conversion (%) Nitrous oxide is a greenhouse gas with an effect 298 times greater than CO2 on the global warming. The industrial sector generates 5% of the total emissions of N2O and they are increasing in the last years. In particular, emissions in nitric acid plants have a particular difficulty in being reduced.

The most effective technologies for the elimination of nitrous oxide in nitric acid plants are catalytic decomposition processes after the ammonia oxidation stage (secondary treatment) or in the tail gas stream (tertiary treatment).

80 60 [N2O] = 1400 ppm [O2] = 3% [H2O] = 0,5% 40 20 0 250 GHSV = 50.330 h-1 300 350 400 Temperature (ºC) 450 Behavior of the novel catalyst with the temperature of reaction

Main innovations and advantages

· Catalysts for tertiary treatment offer the great advantage of not influencing the heart of the nitric acid plant · The catalyst is active at relatively low temperatures (between 250ºC and 500 · C) · The catalyst can work below 300ºC with conversions around 80%.

· The catalyst works with high efficiency under real conditions (in the presence of other tail gas components · O2, H2O) · The catalyst has good stability: 65 h in reaction without decreasing conversion of · N2O, with the presence of H2O and O2.