CSIC has developed a method for the production of nanoporous solids that contain gas inside their

pores. The method is based on magnetron sputtering, but gas consumption is lower in comparison with

conventional sputtering methods carried out in dynamic regime. Experimentally, layers of controlled

thickness of these nanocomposite materials have been successfully obtained. Gas consumption during

the production of these solids was only 0.5% of gas consumption in conventional magnetron sputtering

in dynamic regime.

Industrial partners from electronic or defence sectors or laboratory materials and chemicals products

providers are being sought to collaborate through a patent license agreement.

An offer for Patent Licensing

Suitable to produce solids with embedded scarce gases

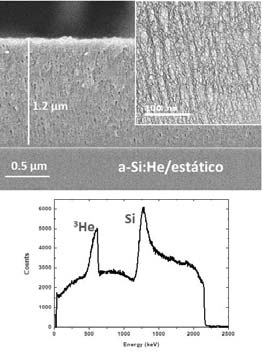

Micrographs of a Si-He layer grown with the developed method in statics conditions. Analysis by proton elastic backscattering of a nanocomposite layer of Si and 3He.

Porous solids with gaseous aggregates can be produced by magnetron sputtering in dynamic regime. However, this method implies a high gas consumption since it requires a constant flow of gas renovation. It becomes a problem when porous solids with scarce, expensive and/or radioactive gases need to be produced.

The method developed by scientific researchers of CSIC allows obtaining porous solids with gaseous aggregates inside the nanopores and in the grain boundaries of the solid. The process is carried out in a magnetron sputtering chamber in statics or quasi-statics conditions. In this type of regimes, a constant volume of gas is kept in the chamber or the process is carried out with a very low gas flow. This allows minimizing gas consumption avoiding constant gas renovation.

Main innovations and advantages

· Gas consumption is less than 0.5% of the gas consumed in dynamicregime.

· It allows to work efficiently with gases such as hydrogen, helium, neon,and their isotopes. It´s relevant for noble gases that don’t formcompounds and stay trapped in condensed state at room conditions.

· Gas trapped inside the pores are up to 1018 atoms/cm2 in layers of 1-3microns of thickness.

· These nanocomposite layers can be used as solids targets (orstandards) in nuclear physics experiments and for research purposes.

· Impurities and residual contaminants contents are similar to thoseobtained in dynamic regime.

· Different materials can be used as matrix: Si, Cu, Ti, Co, Au, Al, W, Pt,Ta, B y C.