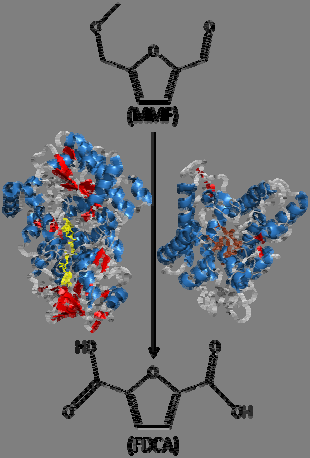

A self-sustained enzymatic cascade reaction

Use of the enzymatic composition for the production of 2,5-furandicarboxylic acid (FDCA) from 5-methoxymethylfurfural (MMF) Nowadays, there is an increase in the need of the substitution of petroleum-based materials with renewable ones. In this regard, FDCA is a promising precursor for the production of renewable and biodegradable bioplastics. FDCA can be obtained from 5-hydroxymethylfurfural (HMF) through the acidic dehydration of fructose, but MMF represents a promising alternative to HMF.

The use of enzymes for the production of FDCA is interesting to substitute the current methods based on chemical catalysts and acid-containing solvents such as acetic acid dilutions.

The procedure developed uses the novel enzymatic composition for the bioconversion of plant-derived, thus, renewable, MMF into FDCA by enzymatic catalysts that only consumes atmospheric oxygen and that can be carried out at room temperature and atmospheric pressure. The MMF is obtained by the acidic dehydration of lignocellulose-derived fructose in the presence of methanol and is supposed to exhibit better storage stability than HMF. It can be used in the industrial production of polyethylene furandicarboxylates (PEFs) using enzymes for FDCA production instead of inorganic catalysts.

Main innovations and advantages

· The method described does not use inorganic catalysts, but enzymesthat accomplish their tasks synergistically at room temperature andatmospheric pressure.

· The method saves energy in comparison with the current techniques,which rely on high temperatures for the production of FDCA, and isenvironmentally-friendly.