CSIC has developed a process for the enzymatic synthesis of alkyl esters of long chain fatty acids in the

presence of an alcohol and an enzymatic preparation with a sterol esterase/lipase covalently

immobilized on magnetic particles functionalized on its surface.

The process increases the yield of the

synthesis of alkyl esters, and allows recovery of the catalyst. The synthesized compounds can be used as

biofuel.

Industrial partners are being sought to use the technology through a patent licence agreement.

An offer for Patent Licensing

Enzymes immobilized on magnetic particles

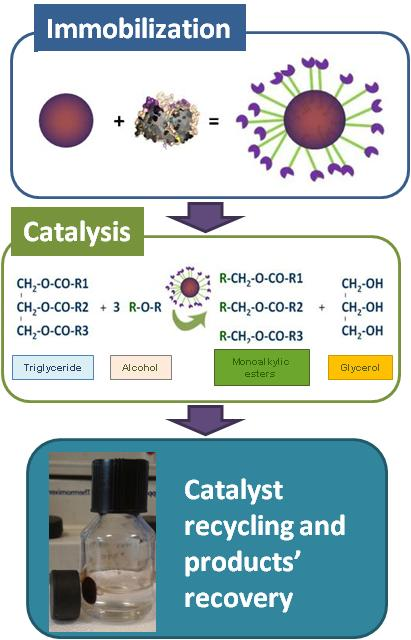

Immobilization of the lipase on magnetic nanoparticles, biodiesel synthesis and catalyst recycling For the production of biodiesel, biofuel based on mixtures of monoalkyl esters of long chain fatty acids from renewable sources, chemical catalysts are currently used mainly for being cheap and high performance, although the process entails a high energetic cost and they are not easily recovered.

The use of enzymatic catalysts for the synthesis of biodiesel is used less because it is a slower process and the enzymes are more expensive However, it has the advantages of being able to recover the end products and reuse them, mainly if the enzymes are immobilized, and that it does not generate toxic waste.

In this invention it has been possible to immobilize a versatile lipase by covalent bonding to functionalized magnetic particles and to use it in the enzymatic synthesis of biodiesel, alkyl esters of long chain fatty acids (methyl esters). The use of the immobilized catalyst allows its recovery, and the sterol esterase/lipase can be used in at least ten reaction cycles without reducing its activity and speed.

The enzymatic synthesis of biodiesel is carried out at mild temperatures, the products (methyl esters and glycerol) are clean, easy to recover, and does not generate contaminant waste.

Main innovations and advantages

· The immobilized enzyme shows an increase in the yield of the biodieselsynthesis process.

· It is possible to recover the enzyme covalently bound to the magneticparticles simply and efficiently, by applying a magnetic field.

· The recovered catalyst maintains its activity and reaction rate for atleast 10 consecutive cycles, which means a saving in the process ofobtaining biodiesel.

· The enzymatic synthesis of biodiesel is environment-friendly.