Never miss an update from Universidad de Alicante

Create your free account to connect with Universidad de Alicante and thousands of other innovative organizations and professionals worldwide

The Institute of Chemical Process Engineering of the University of Alicante has developed a filter that reduces tars and toxic compounds in tobacco smoke by up to 75%.This filter is characterised by one or more tapers arranged between the end that is in contact with the column of tobacco smoke and the end that is in contact with the smoker's mouth. These tapers selectively condense the noxious products without altering the aroma and taste of the tobacco, keeping the sensory perceptions experienced by the smoker intact. This technology is characterised by the fact that it can be easily implemented in conventional filter cigarette manufacturing machines for large-scale production.The technology is patent protected. Companies interested in acquiring this technology for worldwide commercial exploitation are being sought.

TECHNICAL DESCRIPTION

In order to solve the problem described above, a filter has been developed that reduces tars and toxic compounds in tobacco smoke.

This filter comprises one or more tapers arranged between the end that is in contact with the tobacco smoke column and the end that is in contact with the smoker's mouth. These tapers allow tars and other toxic compounds to be selectively condensed.

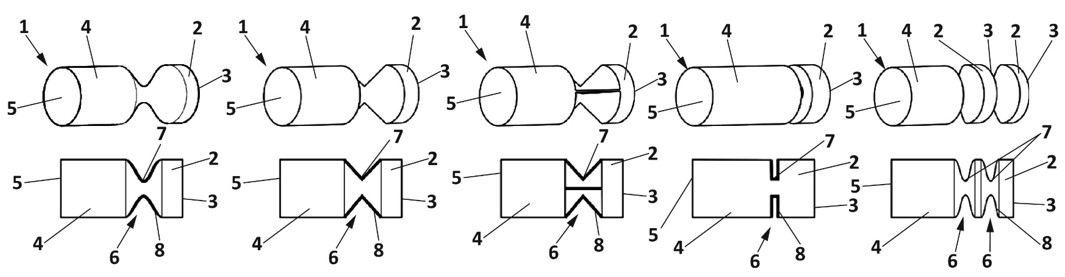

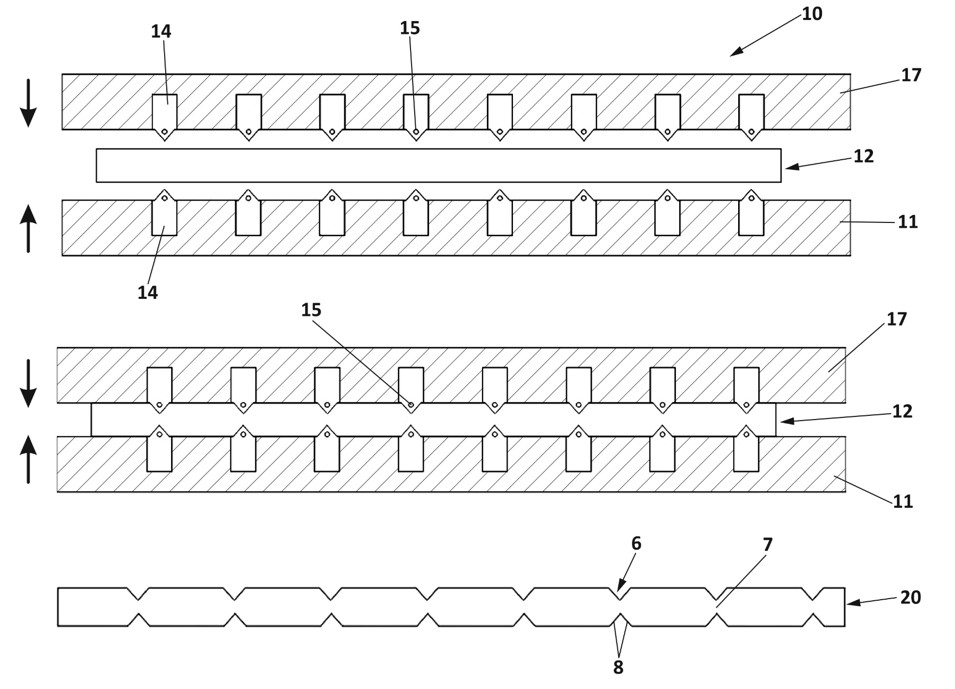

The filter can have different configurations (see Figure 1), all of which are characterised in that they have in common at least one narrowing between two conical (or flat) surfaces joined together by their vertices (or flat walls), giving rise to the free passage section of the tobacco smoke column. When the walls are impermeable, the cross-section is the only exit route for the smoke stream during smoking.

Figure 1: perspective view and side view of five filter variations, with one or more tapers.

When the filter contains two or more tapers, the pass-through sections may have the same (or different) diameters. These diameters have been optimised to maximise the retention of toxic compounds present in tobacco smoke. In addition to the diameter size, the number of tapers has also been optimised, as well as their geometry.

In order to prevent tars and other toxic compounds selectively condensed behind the tapers from coming into contact with the smoker's mouth, a minimum length has been set at the end of the filter closest to the smoker's mouth.

To automate the filter manufacturing process, a cylindrical and elongated fibrous rod containing a set of tapers with different configurations can be used as a starting point, to which a series of cuts are made in order to obtain several filters at the same time.

With regard to the mechanism used in the manufacture of the fibrous rods from which the filters are obtained, at least three different mechanisms can be used:

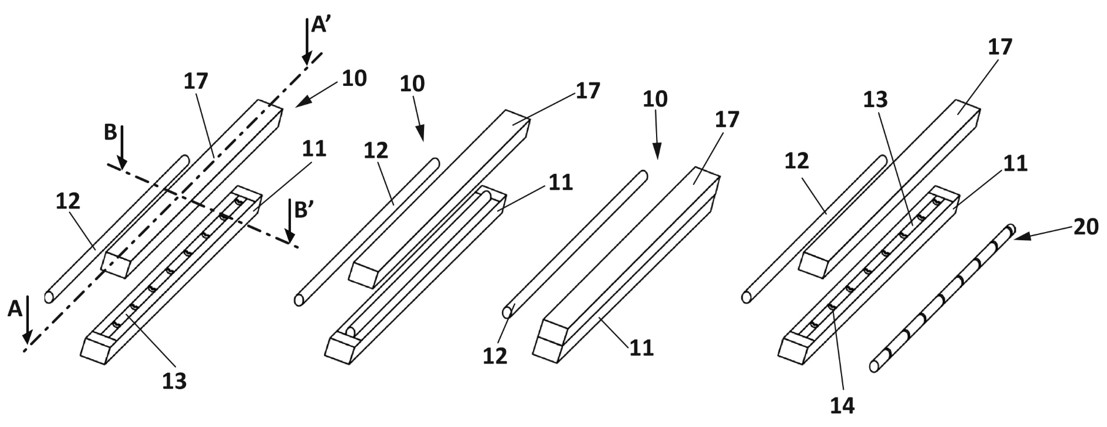

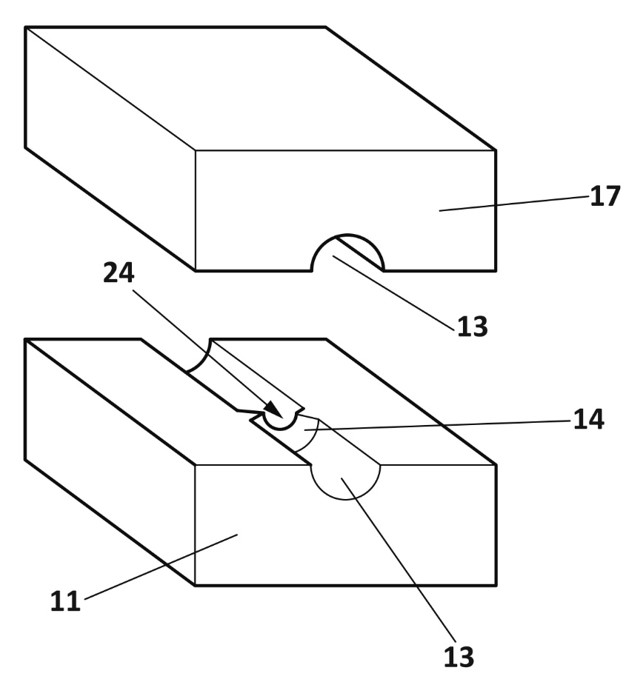

In the first mechanism, there are two half-moulds facing each other, in which one of them (or both) can be moved in opposite directions (see Figure 2). Both half-moulds have a body with an elongated central channel in which the cores that will form the constrictions in the fibrous rod are distributed.

Figure 2: perspective views of operations carried out on a fibrous bar where the semi-mould bodies are longitudinal and directed in opposite directions towards the fibrous bar.

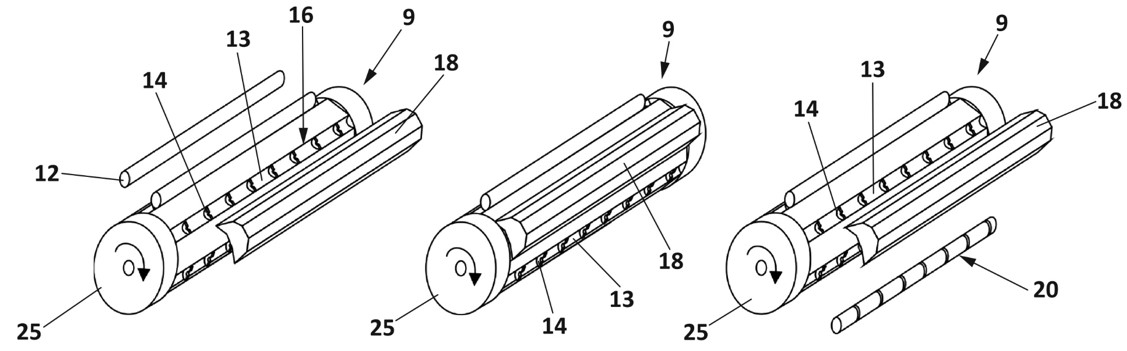

In a second mechanism, there are several half-moulds mounted around a rotating revolver, and each half-mould receives a fibrous rod, and a single second half-mould sequentially faces each of the half-moulds of the rotating revolver after each partial and sequential rotation of the revolver, so that several fibrous rods with tapers are obtained consecutively (see Figure 3).

Figure 3: Sequence of the operation in which the first half-moulds are mounted on a revolver.

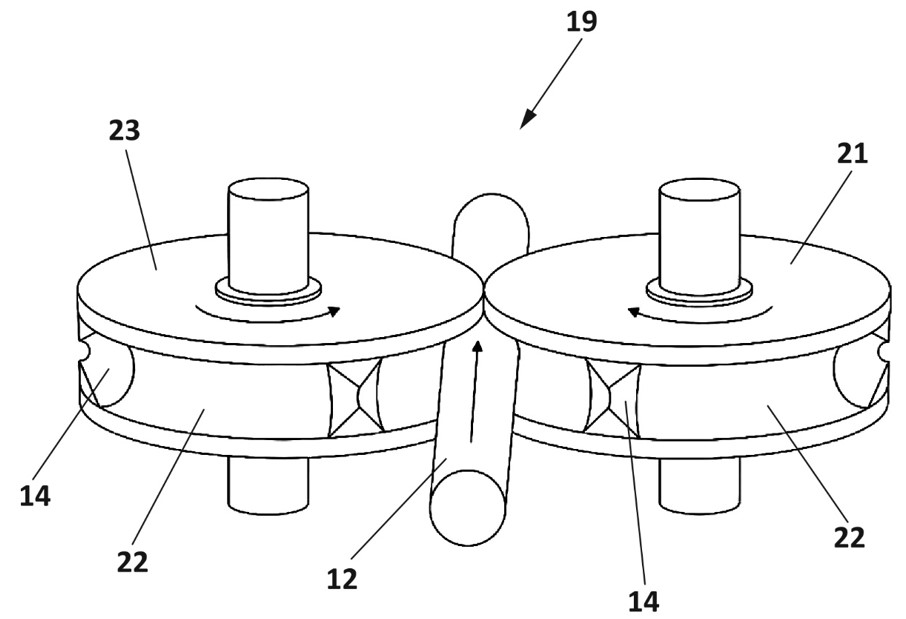

In a third mechanism, the first and second half-moulds are rotating and counter-rotating, and each has a body with a toroidal channel configuration. The channels define the passage sector through which the fibrous rod is introduced tangentially, and the half-moulds rotate in synchronised contact, so that the cores of one half-mould face the cores of the other half-mould to form the narrowings of the fibrous rod as it passes through them (see Figure 4).

Figure 4: View of the rotating half-moulds rotating synchronously while the fibrous rod is inserted tangentially between them.

In any of the above mechanisms, both the first and second half-moulds are formed by a body in which there is a channel defined by a curved lower base of preferably semi-circumferential section, and by a series of transversely distributed internal cores that start at the top and perpendicularly from the base of the channel (see Figure 5).

Figure 5: Perspective view of a portion of the half-moulds showing one of the cores extending from the base of the channel.

Both the canal of the first half-mould and the canal of the second half-mould are slightly larger in diameter than the diameter of the fibrous rod that is inserted between the two canals. In addition, the cores face each other to form the narrowings.

The base of the channel is made of an insulating material, and the cores have heating materials designed so that the pressure between the facing cores, together with the heating of the cores, facilitates the crushing of the fibrous rod and the generation of the constriction.

The configuration of the cores determines the shape of the constriction in the fibrous rod (straight or curved walls, rectangular or round cross-section, etc.). These cores can be fixed or retractable, and the combined action of crushing and heating causes the fibrous rod constrictions (see Figure 6).

Figure 6: Representation of the approaching semi-moulds with their cores heated to generate multiple tapers along the elongated fibrous rod.

TECHNOLOGY ADVANTAGES AND INNOVATIVE ASPECTS

ADVANTAGES OF THE TECHNOLOGY

The main advantages are listed below:

1) Inhaled tars and toxic compounds are significantly reduced. Depending on the final configuration of the filter, the reduction can vary between 50-75% (much higher percentages than other solutions currently available on the market).

2) The taste and aroma of the tobacco is not modified.

3) The sensory perceptions experienced by the smoker are maintained.

4) It allows continuous manufacturing.

5) It can be industrialised on a large scale.

6) Allows to reduce manufacturing costs.

7) The filter can be assembled directly in conventional cigarette machines that use filters.

8) The process is fully automatable.

9) The manufacturing process is very fast.

10) The materials used are environmentally friendly.

11) The raw materials used are commercially available and readily available.

12) Comfort of use for the smoker.

INNOVATIVE ASPECTS OF THE TECHNOLOGY

1. Thanks to the cylindrical and elongated fibrous rod, it can be easily implemented in conventional continuous cigarette manufacturing machines, obtaining as a final product cigarettes assembled with the filters described in the present invention.

2. Each narrowing facilitates condensation and thus the selective reduction of tars and inhaled toxic compounds.

3. Not only the tapers themselves, but the shape of the tapers influences the results obtained in the reduction of tars and other toxic compounds.

4. Each taper has a cross-section that has been optimised to maximise the retention of tars and toxic compounds present in tobacco smoke (between 50-75%) without altering the organoleptic properties and the pleasant sensation of the smoking process.

CURRENT STATE OF DEVELOPMENT

The technology has been developed on a laboratory scale. For this purpose, several smoking experiments have been carried out with 3R4F tobacco from the University of Kentucky (conditioning and smoking conditions as described in ISO 3308 have been used).

Cigarettes of a reference tobacco with its conventional filters were compared to other cigarettes of the same tobacco with filters as described in the present invention. Depending on the filter configuration used (Figure 1), reductions in the inhalation of tars and toxic compounds varying between 50-75% are obtained.

The percentage of reduction depends on different variables, including: the diameter of the free passage section of the smoke column; the number of tapers; the shape of the taper section; the nature of the walls of the taper, etc. and all these variables have been optimised to achieve the maximum reduction in the inhalation of tars and toxic compounds present in tobacco smoke.

Although the technology requires an industrial validation stage, a prototype is currently available for demonstration.

COLLABORATION SOUGHT

Companies interested in acquiring this technology for commercial exploitation are sought:

• Patent licensing agreements.

• Development of new applications.

• Agreements on technology and knowledge transfer.

Company profile sought:

• Manufacturers of conventional filter cigarette manufacturing machines.

• Manufacturers of cigarette filter machines.

• Manufacturers of punching machines for the tobacco industry.

Ahead of the current Coronavirus outbreak, Innoget is fully committed to contributing to mobilizing scientific and expert communities to find a real solution to the Covid-19 pandemic. Therefore, we're supporting worldwide calls and programs that could help in any aspects of the coronavirus crisis.

Is your organization promoting or looking for innovation or research initiatives to mitigate the Covid-19 outbreak? Email us at covid19@innoget.com to list them.

Channeled through Innoget's online open innovation network, initiatives in the health, virology, medicine, or novel technologies applied to human health, among others, are listed and disseminated to Innoget members -ranging from hospitals, research institutes, scientists, businesses, and public administrations- and innovation partners worldwide.

Create your free account to connect with Universidad de Alicante and thousands of other innovative organizations and professionals worldwide

Send a request for information

to Universidad de Alicante

Technology Offers on Innoget are directly posted

and managed by its members as well as evaluation of requests for information. Innoget is the trusted open innovation and science network aimed at directly connect industry needs with professionals online.

Need help requesting additional information or have questions regarding this Technology Offer?

Contact Innoget support