Never miss an update from PepsiCo

Create your free account to connect with PepsiCo and thousands of other innovative organizations and professionals worldwide

New technologies/IP that identify new technologies for oil extraction or preventing absorption

of lipids in a porous matrix e.g. potato chips. These technologies can be outside of the food

industry such as pharmaceutical, petrochemical to enable oil/hydrophobic fluid removal/reduction.

Key areas of focus:

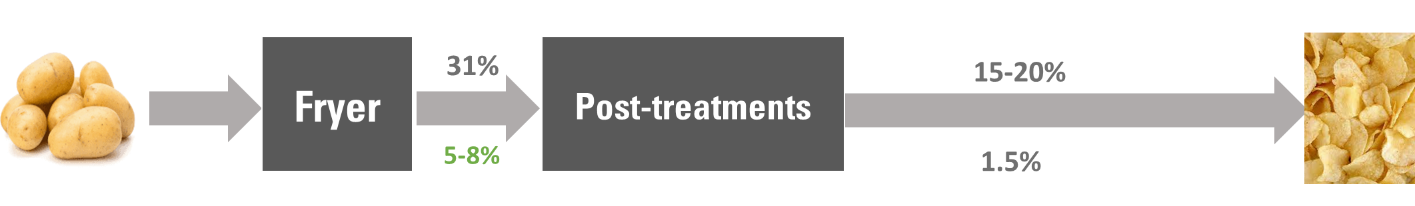

1) Tech limits absorption of hydrophobic fluids (e.g. high temperature post frying to

promote oil drainage)

2) Tech that extracts hydrophobic fluids (e.g. steam stripping, centrifuge, super-critical CO2

extraction, ultrasonic)

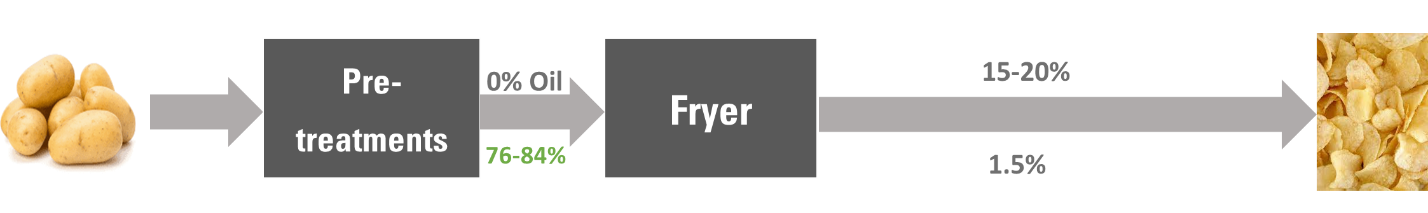

3) Tech that prevents creation of a porous matrix when exposed to thermal energy (e.g.

(pre-treatments such as pulse electric field))

Low Fat Potato Chip (PC) solutions continue to be a high business priority and have only recently elevated with our Pep + organizational commitments. There are also varying needs being driven by the regulatory and competitor environment. Pep R&D is looking to identify new technologies within food, pharmaceutical and petrochemical industries to enable extraction or prevention of absorption of lipids into a porous matrix.

The primary goal of the search is to identify new technologies for oil extraction or preventing absorption of lipids in a porous matrix. The secondary goal is to explore technologies that can reduce porosity or prevent creation of highly porous matrix when a solvent (such as water) is removed from a starch-based substrate like potato due to thermal energy.

Multiple low fat process solutions for potato chips exist today – steam stripping, centrifuge post frying, surface starch to reduce oil absorption, higher temperature post frying to promote oil draining from chip surface are the primary ones. All of these have tradeoffs:

1) Cost/Capacity,

2) Product, AND/OR 3) Limited reduction.

Significant advancement in the technologies listed above or a combination of the technologies that improve fat reduction with minimal impact to product attributes would also be of interest.

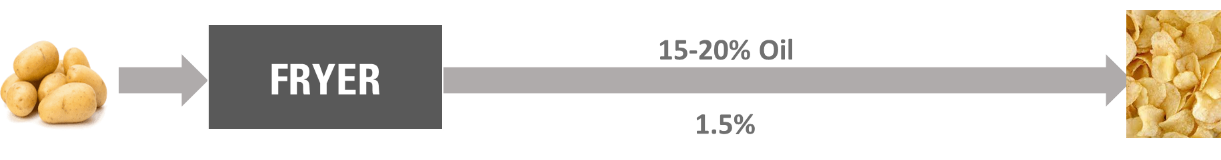

Overview of the current frying process:

">https://www.youtube.com/watch?v=ws_K9Cxs-uE

Key Success Criteria

Must-have requirements:

- Reduce absorption/ strips off lipids by ~50% from porous matrices due to vapor vacuum condensation

- Tested at pilot scale & has potential to be scalable

- Partner should have bench testing capability.

- Analytical testing of capability: primarily oil content & moisture of product (if food related)

- Technology should be demonstrated on whole chips (not crushed) if tested with food products

Preferred requirements:

- Demonstrated as a continuous process

- Technology compatible with food (materials used can be replaced with food grade)

- Does not involve more than 2-unit operations in addition to the current process.

- Modification of current unit operations is preferred. The goal of these is to have minimal footprint.

Possible Approaches:

Solutions of interest

in order of preference:

Tier 1: Ideal solution would be something that can be retrofitted into our current system, works as a continuous process & does not require a significant footprint (less than 15 m long); operating cost less than 3 million at rated capacity of 3000 kg/hr.

Tier 2: Partnership to scale technologies that can achieve the level of reduction desired and have been demonstrated at pilot scale and show potential to be scalable. Pepsico will partner with the researcher to understand footprint and operating cost at the scale desired.

Tier 3: Research that has explored a combination of technologies such as steam stripping, centrifuge post frying, surface starch to reduce oil absorption, higher temperature post frying to promote oil draining from chip surface and has achieved some degree of success at reducing oil absorption/ increase oil stripping to more than 20% with minimal impact to product characteristics

Tier 4: Pre-treatments such as use of non-toxic non-oil wettable coatings (preferably non-oil soluble), oil modification/ non-nutritive oils as well as process/product/ingredient solves for the substrate which help to reduce porosity of product.

Approaches Not of Interest:

First principle/bench-top techniques that are not scalable.

Technologies previously explored such as steam stripping, centrifuge post frying, surface starch to reduce oil absorption, fabricated and baked PC, higher temperature post frying to promote oil draining from chip surface unless there is significant advancement in the field or a combination of techniques enabling increased reduction/ improved efficiency.

Use of coatings to prevent oil absorption as the primary mechanism of oil reduction unless more than 35% reduction and if the coatings don’t get dissolved in oil

Use of any salt-based marination techniques. Non-salt-based marination would be of interest.

Preferred Collaboration types:

PepsiCo is open to a range of collaboration types

Resources Available when collaborating with PepsiCo

PepsiCo can partner to help with scaling up of technology if it has been demonstrated at pilot scale and has potential to be scalable.

Our mission is to advance GU’s innovations through strategic alliances and new venture creation, to facilitate the translation of research breakthroughs into tangible solutions, and to cultivate a dynamic and inclusive environment for entrepreneurship. We advance this mission in support of the GU community and for the benefit of society.

Create your free account to connect with PepsiCo and thousands of other innovative organizations and professionals worldwide

Innovation Needs on Innoget are directly posted and managed by its members as well as evaluation of proposals. Innoget is the trusted open innovation and science network aimed at directly connect industry needs with professionals online.

Need help submitting your proposal or have questions regarding this Innovation Need?

Contact Innoget support

In the solution proposal submission form: