- Anonymous Organization

- From European Union

- Responsive

- Project Size Range : Strategic project backed by large scale funding €

- Posted by

Desired outcome

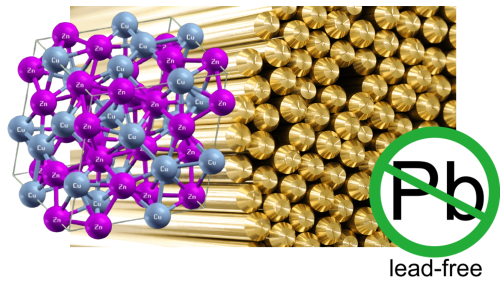

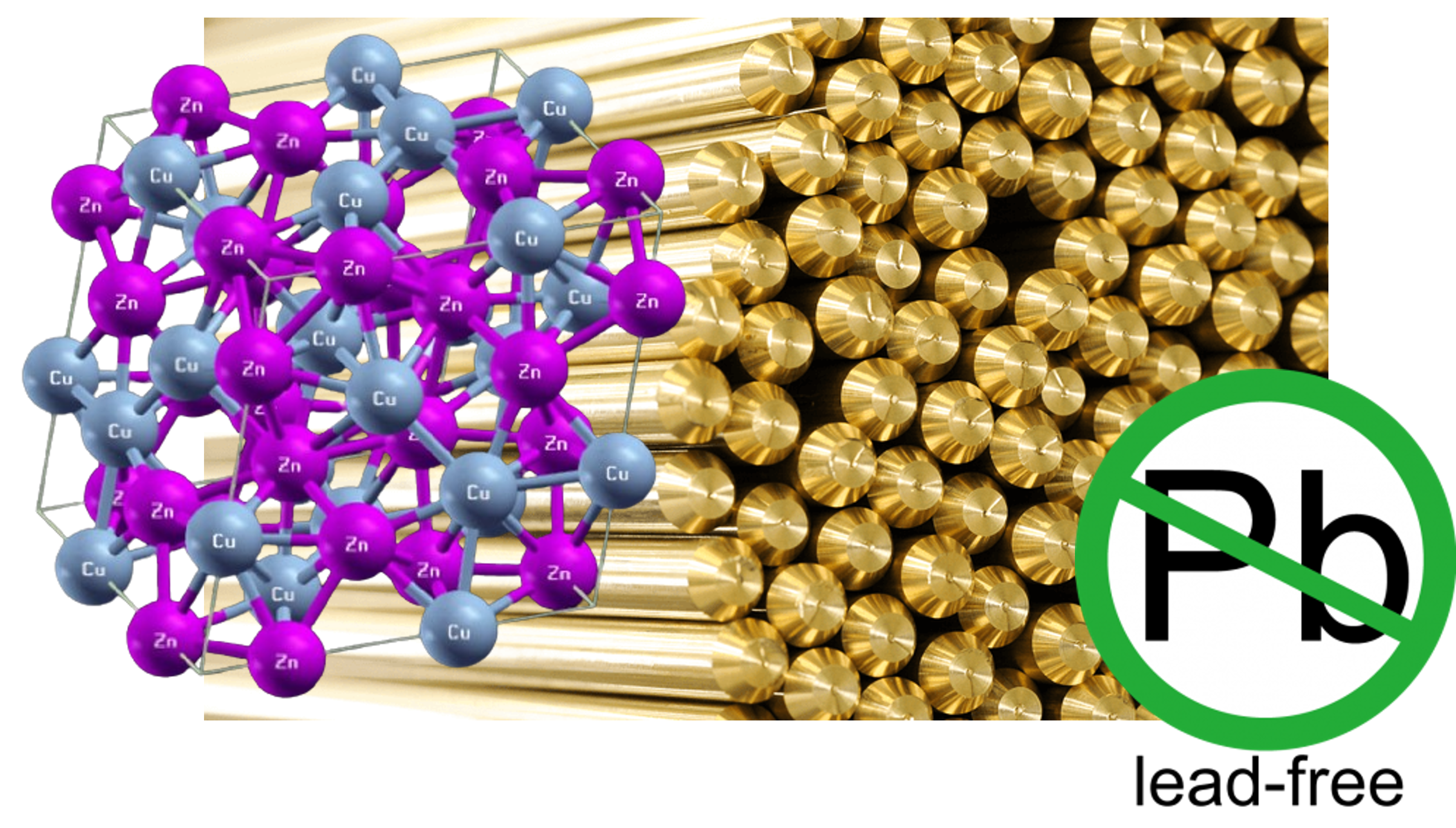

A leading fast moving consumer goods company that manufactures stationery products in EU is looking for an alternative to the leaded brass currently used to produce small size factor cylindrical parts for its products. The material should have a high machinability (eg microdrilling, microturning) and allows to achieve high production rates.

The solution should be either a lead-free brass or/and Lead-free Nickel Silver alloy with specific properties to ensure long tool durability, easy chip fragmentation, and good surface finishing of the manufactured parts. It shall also comply with the current consumer product safety regulations (REACH, CPSIA, HSE) and not alter the chip recycling process.

Details of the Innovation Need

Solution :

- Geography: Solutions sought from any geographic location, with emphasis on marketability in the EU and US.

- Development Phase: Targeting solutions beyond TRL 3, focusing on experimental proof of concept.

Company's Background and Insights :

Our technology roadmap includes the progressive replacement of leaded brass with alternative solutions that do not require the presence of this element. Future regulations in EU and US may enforce a significant reduction of the allowed lead content in consumer goods

Business objectives to be achieved with the solution

The company aims to keep the same production throughput as today, without significantly affecting cost and without altering the production performance and machine layouts that are currently adopted by its manufacturing plants.

Tested/ Discarded solutions:

The only solution currently available in the market is lead-free stainless steel. However, the widespread adoption of this material would expose our company to different risks, such as : low productivity, increased cost, supply difficulties such as shortages.

Other experimental brass alloys with low lead content have been tested over the years, same as lead free brass alloys with added elements such as Bismuth, Indium and Silicium. However, the results wereunsatisfactory, namely, excessive tool wear, insufficient chip fragmentation, difficult to recycle chips, and poor production yields.

Must haves:

Technical requirements:

- Lead content <500ppm

- High machinability (eg microdrilling, microturning)

- Must allow long tool durability

- Easy chip evacuation

- Good surface finishing of the parts

- Material recyclability

Business requirements :

- High production rates

- Material availability at least 100Kg for testing stage

- Proven ability to scale-up to FMCG production industry standards

- Material cost comparable to current (< €15/kg)

- Low impact on manufacturing flow

- Low impact on recyclability procedures

Legal / Environmental

Nice to haves

- Lead content <100ppm

- Lightweight material

- Cost-effective solution

- Sustainable solution ( not aggressive chemistry, recyclability, low environmental impact , reduced waste generation)

Opportunity :Preferred partnership options include R&D contracts, joint development ventures, supply agreements, and patent sales. Upon validating and demonstrating the feasibility of the proposed solution, the parties may establish a contractual agreement to transfer technology usage rights to the company.

Business timelines

2024 Q3 Testing at R&D level.

2025 Q1 Technical feasibility assessment

2025 Q4 Testing on an industrial scale

Related Keywords

About Us

We stand as a global frontrunner in fast-moving consumer goods, boasting significant innovation across various product categories. Our robust manufacturing and commercial footprint spans the globe, encompassing retail, B2B, D2C, and beyond, alongside an extensive portfolio of products. With a formidable innovation roadmap, we aim to bolster further through strategic collaborations, fostering human-centric and eco-friendly innovative solutions and products.

About Innovation Needs

Innovation Needs on Innoget are directly posted and managed by its members as well as evaluation of proposals. Innoget is the trusted open innovation and science network aimed at directly connect industry needs with professionals online.